Testing Equipments Supplier

ISO9001:2015 Certified

ISO9001:2015 Certified  ISO9001:2015 Certified

ISO9001:2015 Certified

In the evolving world of materials testing and research, precise measurement and analysis of bituminous materials are critical for ensuring the durability and performance of pavements. One essential tool that has become increasingly important in this field is the PAV system (Pressure Aging Vessel system), widely used for simulating the long-term aging of asphalt binders under controlled conditions.

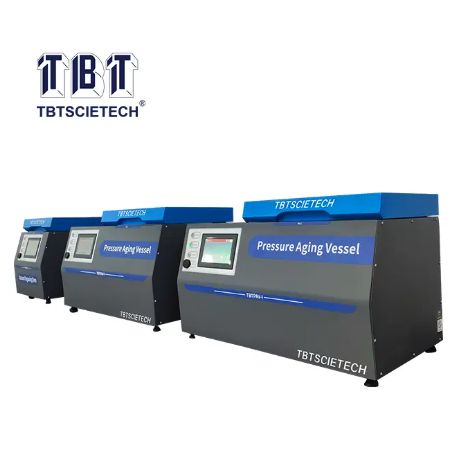

This article will comprehensively explore what a PAV system is, its working principles, applications, latest trends, and how Nanjing T-Bota Scietech Instruments & Equipment Co., Ltd., a professional supplier of high-quality testing instruments, can support laboratories and pavement testing facilities with reliable PAV systems to enhance accuracy and efficiency in asphalt testing.

A PAV system (Pressure Aging Vessel system) is a laboratory instrument designed to simulate the long-term oxidative aging of asphalt binders under elevated pressure and temperature, replicating the aging that occurs in the field over years of service.

The main objectives of using a PAV system include:

Evaluating the long-term durability of asphalt binders.

Simulating the oxidation and volatilization processes that occur in pavements.

Assisting in the performance grading of asphalt as per Superpave specifications.

By replicating field aging, the PAV system provides valuable data for designing pavements that withstand environmental and traffic stresses over time.

The PAV (Pressure Aging Vessel) system is a sophisticated laboratory tool designed to accelerate the aging process of asphalt binders in a controlled manner. It operates by subjecting asphalt binder samples, which have been previously aged using the Rolling Thin Film Oven (RTFO), to a combination of high pressure (typically 2.1 MPa) and high temperature (usually between 100°C and 110°C) within a sealed environment for a period of 20 hours. This rigorous process effectively simulates the oxidative aging that asphalt binders would experience over five to ten years in real-world conditions, thereby allowing researchers and engineers to study the long-term behavior of these materials in a much shorter timeframe.

Loading the Samples: The process begins with carefully loading the asphalt binder samples into stainless steel pans. These pans are placed inside the PAV vessel, ensuring that they are securely positioned to withstand the high-pressure and high-temperature conditions that follow.

Sealing and Pressurizing: Once the samples are in place, the vessel is sealed tightly. Compressed air is then introduced to pressurize the vessel to the required level of 2.1 MPa. This high-pressure environment is crucial for accelerating the aging process by increasing the rate of oxidation.

Heating the Vessel: The next step involves heating the vessel to the desired testing temperature, which is typically maintained between 100°C and 110°C. This elevated temperature further accelerates the oxidative reactions within the asphalt binder, mimicking the long-term exposure to heat and air that occurs in actual pavement applications.

Maintaining Conditions: The PAV system is designed to maintain both the pressure and temperature at their set levels for the entire duration of the test, which is usually 20 hours. During this time, the asphalt binder undergoes significant oxidative aging, resulting in changes to its physical and chemical properties that are indicative of long-term performance in the field.

Cooling and Depressurizing: After the aging process is complete, the vessel is allowed to cool down gradually. Once the temperature has sufficiently decreased, the pressure is released, and the vessel is depressurized. The aged samples are then carefully retrieved from the stainless steel pans for further testing and analysis.

This controlled and systematic approach ensures that the aging process is reproducible and reliable, providing consistent results that can be used for accurate performance testing of asphalt binders.

The durability and longevity of pavement structures are significantly influenced by the aging characteristics of the asphalt binders used in their construction. While the Rolling Thin Film Oven (RTFO) is effective in simulating the short-term aging that occurs during the mixing and laying processes, it does not fully capture the long-term oxidative aging that asphalt binders experience throughout their service life. This is where the PAV system plays a crucial role.

Evaluating Long-Term Performance: By simulating long-term oxidative aging, the PAV system allows researchers and engineers to evaluate critical performance properties of asphalt binders, such as rutting resistance (the ability to resist permanent deformation under repeated traffic loads), cracking resistance (the ability to withstand the formation of cracks due to aging and environmental factors), and fatigue resistance (the ability to endure repeated stress without failure). These evaluations are essential for predicting how well a pavement will perform over its entire service life.

Predicting Pavement Performance: The insights gained from PAV testing enable more accurate predictions of long-term pavement performance. This information is invaluable for designing and constructing pavements that will meet the demands of heavy traffic, harsh weather conditions, and extended service life, thereby reducing maintenance costs and improving overall road safety.

Ensuring Compliance with Standards: The PAV system is an integral part of the Superpave and ASTM standards (such as ASTM D6521), which are widely recognized and used in the asphalt industry. By using the PAV system, researchers and engineers can ensure that their asphalt binders and mixtures comply with these rigorous standards, thereby guaranteeing a high level of quality and performance.

Developing High-Performance Mixtures: The PAV system provides a valuable tool for developing and selecting durable, high-performance asphalt mixtures. By testing different formulations under accelerated aging conditions, researchers can identify the most resilient and long-lasting binders and mixtures, leading to the creation of more sustainable and cost-effective pavement solutions.

Performance Grading (PG) under the Superpave system relies on the results obtained from PAV-aged asphalt binders to determine their suitability under different climatic and traffic conditions.

Testing Phase | Purpose | Equipment Used |

Short-term aging | Simulate plant mixing and laying conditions | Rolling Thin Film Oven (RTFO) |

Long-term aging | Simulate 5-10 years of field aging | PAV System |

Performance testing | Evaluate high and low-temperature properties | Dynamic Shear Rheometer (DSR), Bending Beam Rheometer (BBR) |

The PAV system thus plays a central role in ensuring the reliability of PG grading for asphalt binders.

When selecting a PAV system for your laboratory, it is crucial to consider several key features that ensure optimal performance, reliability, and safety. A high-quality PAV system should possess the following characteristics:

The system must be capable of maintaining a consistent pressure of 2.1 MPa throughout the entire aging process. This level of precision is essential because even slight deviations in pressure can significantly impact the accuracy of the aging simulation. A reliable PAV system should have advanced pressure control mechanisms that ensure stability and uniformity, providing consistent results across multiple tests.

Uniform heating across the vessel is vital for accurate aging simulations. The PAV system should be able to maintain the temperature within a narrow range of ±0.5°C. This precision ensures that all samples within the vessel are subjected to the same conditions, thereby eliminating variability in test results. Advanced temperature control systems, such as PID controllers, are often employed to achieve this level of accuracy.

Efficiency is a key consideration in laboratory operations. A high-quality PAV system should have the capability to handle multiple samples simultaneously. This feature not only increases throughput but also allows for comparative testing of different asphalt binders or formulations in a single run. The ability to process multiple samples at once can significantly reduce the time and resources required for extensive testing programs.

Safety is paramount when working with high-pressure and high-temperature equipment. A well-designed PAV system should include overpressure protection mechanisms to prevent the vessel from exceeding safe operating limits. Secure locking mechanisms ensure that the vessel remains sealed during the test, preventing accidental openings. Additionally, clear indicators and alarms should be in place to alert operators of any potential issues, such as pressure or temperature deviations.

User-friendliness is another important aspect of a high-quality PAV system. The interface should be intuitive and easy to navigate, with clear status indicators that provide real-time information on the test progress. Automated logging of pressure and temperature data not only simplifies the operation but also enhances the accuracy and reproducibility of the test results. These features make the system accessible to both experienced technicians and new users, ensuring smooth and efficient operation.

The PAV system is a versatile and essential tool in the asphalt industry, with a wide range of applications that cater to various needs in research, quality control, forensic analysis, and material development.

In asphalt research laboratories, the PAV system is indispensable for developing high-performance asphalt binders. Researchers use the PAV system to evaluate the aging characteristics of new formulations and additives, such as polymer-modified asphalts, bio-based binders, and rejuvenators. By simulating long-term aging, they can gain insights into how these materials will perform over their service life, leading to the development of more durable and sustainable asphalt solutions.

Quality control is a critical aspect of asphalt production and construction. The PAV system is widely used to ensure that asphalt binders comply with contract specifications and performance grades. By subjecting binders to accelerated aging, quality control engineers can verify that the materials meet the required durability and performance standards before they are used in pavement construction. This helps in reducing the risk of premature failure and ensures the longevity of the pavement.

When pavement failures occur, it is essential to understand the underlying causes to prevent future issues. The PAV system plays a crucial role in pavement forensic analysis by replicating field conditions in the laboratory. Investigators can use the PAV system to study the behavior of asphalt binders under long-term aging conditions, identifying potential weaknesses or deficiencies in the materials. This information can then be used to improve pavement design and construction practices.

The development of new and improved asphalt materials is an ongoing process driven by the need for more sustainable, cost-effective, and high-performance solutions. The PAV system is an invaluable tool in this process, allowing researchers to evaluate the performance of modified binders under long-term aging conditions. For example, polymer-modified asphalts are often tested using the PAV system to assess their resistance to aging and their ability to maintain performance over time. This helps in selecting the most suitable materials for specific applications and environmental conditions.

Modern PAV systems feature automated pressure and temperature control, reducing manual intervention and human error while ensuring test consistency. Integrated data logging enables the recording of pressure and temperature profiles for quality control and reporting.

Manufacturers are incorporating enhanced safety features, such as automatic depressurization, overpressure alarms, and dual safety locking systems, ensuring safe operation during testing.

Advanced PAV systems now include touchscreen digital interfaces with programmable test parameters, pre-set standards, and live monitoring for operational efficiency.

Optimized heating systems and thermal insulation reduce energy consumption during the long testing cycle, contributing to cost savings and sustainability goals.

Some PAV systems now support integration with LIMS for automated data transfer, traceability, and centralized reporting, streamlining laboratory operations.

A PAV system (Pressure Aging Vessel system) is a laboratory instrument designed to simulate the long-term oxidative aging of asphalt binders under elevated pressure and temperature. It is crucial for evaluating the long-term durability of asphalt binders, predicting pavement performance, ensuring compliance with standards like Superpave and ASTM, and developing high-performance asphalt mixtures.

The PAV system accelerates the aging process of asphalt binders by subjecting them to high pressure (typically 2.1 MPa) and high temperature (usually between 100°C and 110°C) within a sealed environment for a period of 20 hours. This process simulates the oxidative aging that occurs over five to ten years in real-world conditions.

Accurate Pressure Control: Maintains consistent pressure at 2.1 MPa throughout the aging process.

Precise Temperature Control: Uniform heating with temperature control within ±0.5°C.

Sample Capacity: Capable of handling multiple samples simultaneously to increase efficiency.

Safety Features: Includes overpressure protection, secure locking mechanisms, and clear indicators.

Ease of Operation: User-friendly interface, clear status indicators, and automated pressure/temperature logging.

Compliance with Standards: Meets ASTM D6521 and AASHTO R28 specifications.

A PAV system can enhance your laboratory’s capabilities by providing reliable and accurate long-term aging simulations. It ensures consistent results, helps in designing longer-lasting pavements, and contributes to compliance with industry standards. By using a high-quality PAV system, you can improve the efficiency and accuracy of your asphalt testing processes.

A PAV system is an indispensable tool in the evaluation and development of asphalt binders, providing a reliable simulation of long-term oxidative aging in a controlled laboratory environment. By replicating years of field aging within 20 hours, the PAV system enables researchers and engineers to predict the long-term performance of pavements, ensuring quality, durability, and compliance with Superpave specifications.

Nanjing T-Bota Scietech Instruments & Equipment Co., Ltd. offers high-quality, advanced PAV systems designed to meet the rigorous demands of laboratories and testing facilities. By integrating a reliable PAV system into your testing process, you can enhance your laboratory’s capabilities, ensure consistent results, and contribute to the construction of longer-lasting pavements. Ready to upgrade your asphalt testing capabilities with a PAV system? Contact T-Bota to learn how our solutions can support your laboratory’s needs and drive your projects forward with precision and efficiency.